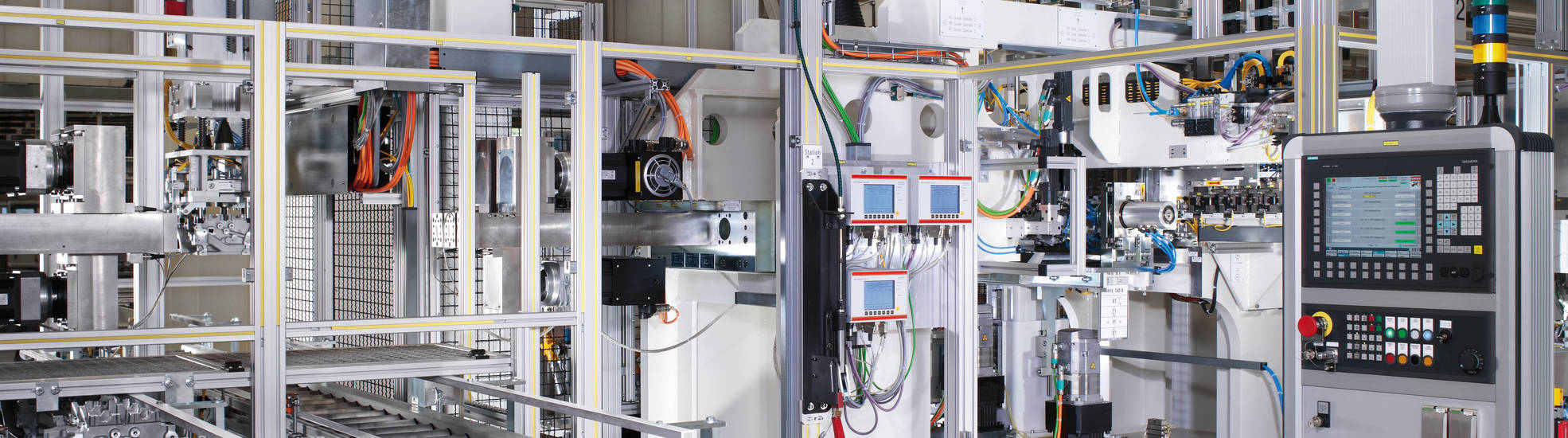

Customized Assembly Machines

FEED

- Feed

- Separate

- Orientate

- Move

- Test

PREPARE

- Cool

- Heat

- Oil

- Spray

- Mark

ASSEMBLE

- Attach

- Plug

- Bolt

- Insert

- Press on

- Screw in

TEST

- Monitor torque and angle

- Measure force and distance

- Check geometry

- Measure leakage rate via flow or pressure decay

Delivery Program

Whether a manual assembly station or fully automatic assembly line, AMT creates solutions that optimally fit into our customer’s production environments and satisfy their economic conditions.

Our delivery program includes:

- Assembly machines for the assembly of cylinder heads and motor blocks

- Assembly lines for the small series assembly of engines

- Assembly stations for wheel carriers and axles

Assembly systems for other parts (e.g. oil pumps, balance shaft housings, camshaft carrier modules, exhaust turbo-chargers, vacuum modules, airbags, air suspensions) and for different processes (e.g. valve clearance measuring station).

Scope of Delivery

Our scope of delivery includes all of the components relevant for assembly such as:

- Manual work stations

- Semi and fully automatic assembly stations

- Bolt and insertion systems

- Handling devices

- Robots

- Transportation systems with part carriers

- Work piece holders

- Test and inspection systems